Geometric Calibration of Time-of-Flight Laser Scanning Systems

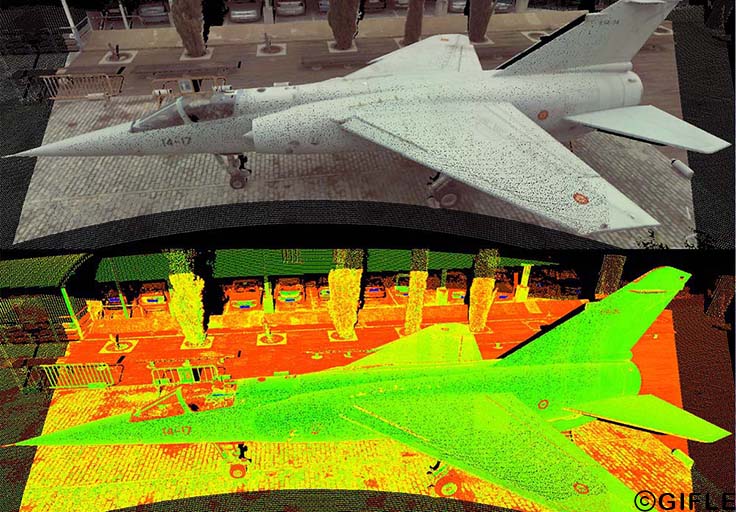

Instruments lacking of systematic errors is imperative in any professional area. Specifically speaking of surveying devices, the geometric calibration process can be defined as the elimination of systematic errors from their angular and range measurements. This fact is generally associated with sending your laser scanner to your manufacturer, and involves several issues: sending the equipment, unavailability of it during the calibration time, ignorance about the approach and last but not least the economic cost. Furthermore, it must be taken into consideration the periodicity for recalibration due to sensitivity of the instrument and the accuracy required by the user.

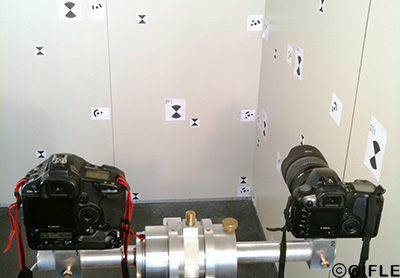

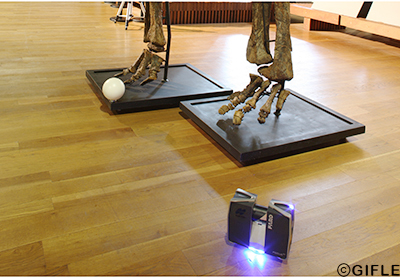

GIFLE suggest the application of a self-calibration mathematical model combined with a statistical model analysis. This approach allows you to obtain a set of additional calibration parameters (internal orientation parameters of the laser scanner) which describe the systematic errors of your time-of-flight laser scanners, either pulse-based or phase-based. The consequent application of such set of calibration parameters on the laser raw data will provide the user error-free point clouds. The geometric calibration will require the materialization and measurement of a reference network. There are two possible ways to carry out the calibration: first, sending us your laser scanning (and we keep going); second, sending us the data files.